Laser cleaning is an eco-friendly alternative to the more traditional high-pressure water or ultrasonic cleaning. These methods usually involve a lot of waste that must be handled correctly. Laser cleaning has no waste except for a filter that needs to be changed occasionally – just like a household vacuum cleaner.

Another aspect is safety – since lasers use no chemicals or solvents of any kind, the personnel operating the machine doesn’t need any safety equipment. The laser is completely encapsulated and has many safety features installed to stop the laser if there is any attempt to open the machine while it is running.

How does laser cleaning work?

Laser cleaning works by vaporizing the ink at a molecular level and ejecting it from the surface of the anilox. This is done by firing many thousands of short pulses of light per second with a specific wavelength that is absorbed by the ink. The pulses are high in power, but very short in duration. This is crucial in controlling the power delivered to the surface of the anilox.

The laser light is invisible to the human eye, but the plasma generated emits a bright white color, which is very noticeable.

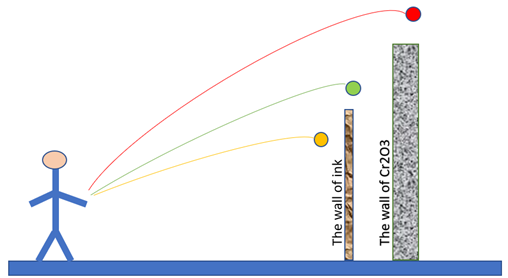

Controlling the power is important – more is not necessarily better. Different materials have different absorption/power thresholds – the threshold for ink is lower than the ceramic of the anilox. This allows us to remove only the ink and not damage the underlying anilox.

Imagine a person throwing a ball over a wall. If you don’t throw the ball hard enough it will never make it over (yellow ball). Throw it just right and it will make it between the two walls of the ink and ceramic (green ball). Throw it too hard and you will overshoot the back wall and risk damaging the ceramic (red ball).

Laser engineer, Martin Bo Augustinus, sums up the advantages: “Laser cleaning is efficient, it is very user friendly, there is little to no waste, and it is considered a very eco-friendly alternative cleaning solution. “