A Scandinavian customer in a Swedish packaging company known for its sustainable and innovative...

Would you like to know more about our environmental solutions? We will guide you through different options of environmental actions that can make a difference in a company's profit.

Fill out this form and learn more about our environmental solutions, so you can improve the sustainability of your Flexo Wash unit even more.

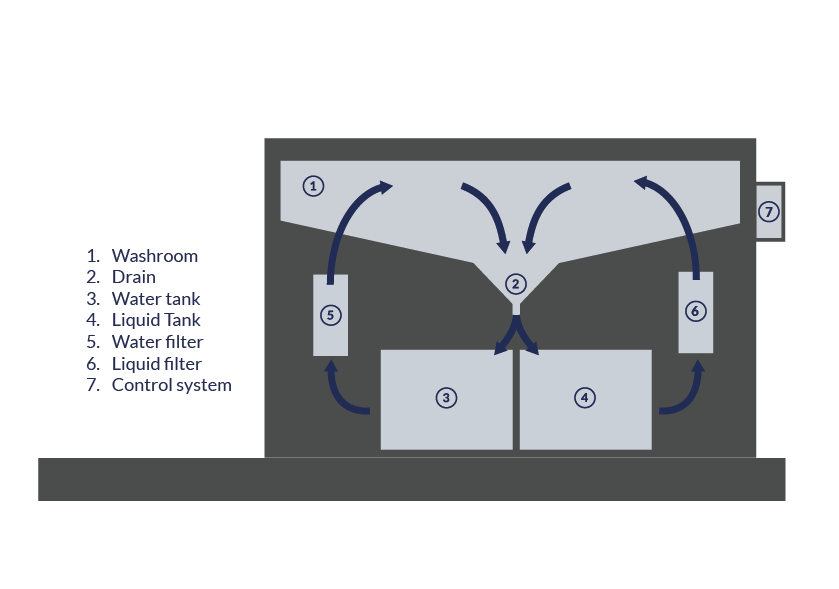

The draining takes approx. 5 minutes and is designed to ensure that as much liquid as possible comes back through an automatic drain valve to the tank to be reused. No matter the number of tanks all liquid will be filtered and reused.

The parts are rinsed with water or the same liquid as for wash, leaving the parts ready for immediate use (WR). In WRO-units the parts are rinsed with fresh water from local water supply.

At Flexo Wash, it is important for us to contribute to a greener printing industry without compromising cleaning quality. Our products are designed for optimal reuse, better drainage, and reduced water and cleaning liquid consumption—a commitment embedded in our machines, embodying the "Flexo Wash way."

Sustainability is a part of our product design and corporate values. We've committed to minimize the environmental impact as part of our new mission. One of the significant steps we've taken towards this commitment is the development of our filtration unit and recirculation unit. In addition to our filtration and recirculation units, our sustainability extends to the liquids we provide.

Our control system on the machines is optimized with our intelligent liquids so that the cleaning cycle is time-optimized.

Our drain is tilted and optimized to make sure all liquid and water go to the tanks.

The filter is designed to filter the ink residue and separate it from liquid and water.

Liquid and water are re-used for multiple cleaning cycles.

Fill out this form and learn more about our environmental solutions, so you can improve the sustainability of your Flexo Wash unit even more.

"It is designed to separate ink residues from the cleaning liquid, thus making it possible to reuse the liquid and prolong its lifetime"

The Filtration system is designed to separate ink residues from the cleaning liquid, thus making it possible to reuse the liquid and prolong its lifetime.

Depending on your individual needs, we will guide you in choosing the right solution for you.

The system can be used with the following units:

PK ECO Maxi with Filtration Unit

"You reduce your water consumption which saves you both money and is better for the environment"

The Recirculation system is designed for reuse of the rinse water in a closed loop system. The system is controlled by several sensors continuously measuring the pH values and liquid levels. The process runs independent of the washing unit.

The process of the Recirculation unit will ensure that the rinse water can be reused in the FW cleaning unit, reducing the amount of wastewater to a minimum. In this way you will still have a high-quality cleaning.

The system can be used with the following units:

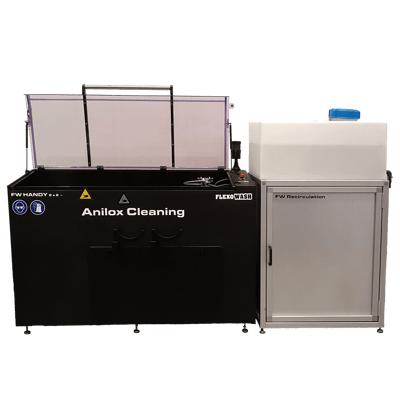

FW Handy midi 2x2 with Recirculation Unit

FW Handy midi 2x2 with Recirculation Unit

A Scandinavian customer in a Swedish packaging company known for its sustainable and innovative...

Written by Dea Jaqué

In today’s competitive printing landscape, every minute of downtime costs money, and every quality...

Written by Dea Jaqué

As the year draws to a close, it’s time to evaluate which areas of the production setup can be...

Written by Dea Jaqué