Elevate your print quality

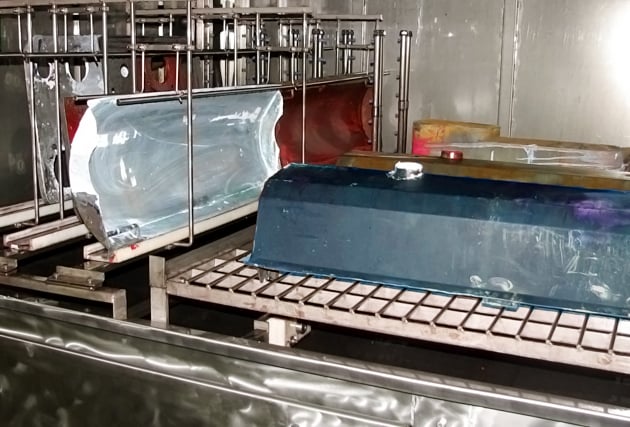

The fully automatic washing units are designed to wash ink trays, doctor blades, aniloxes and other removable press parts used with water-based ink, solvent-based ink, or UV ink.

Download product catalogue:

Fill out the form

To download our brochures and catalogs

Quick & easy operation

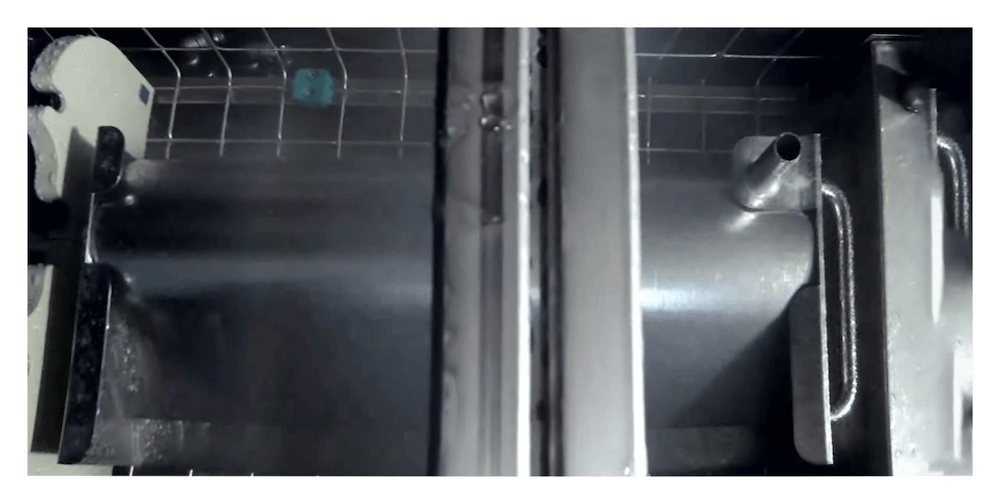

The parts washers from Flexo Wash have a Wash & Rinse system with two separate tanks which offers an automatic two-stage cleaning process, where the first stage is for cleaning and the second stage is for rinsing.

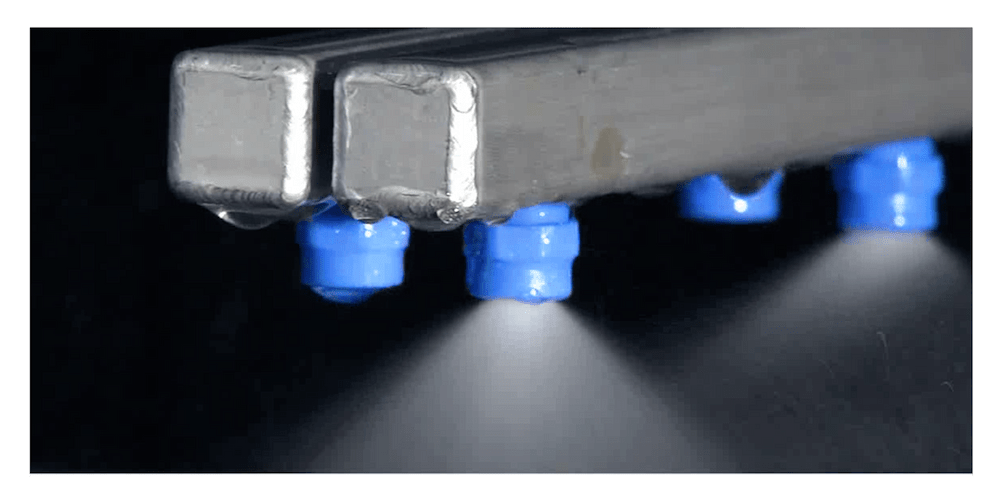

The parts are cleaned by a moving nozzle arm, spraying cleaning and rinse liquid from below and above.

The system is easy to use and with a customized grid you can have the wash room area made to fit your required press parts in one cleaning cycle.

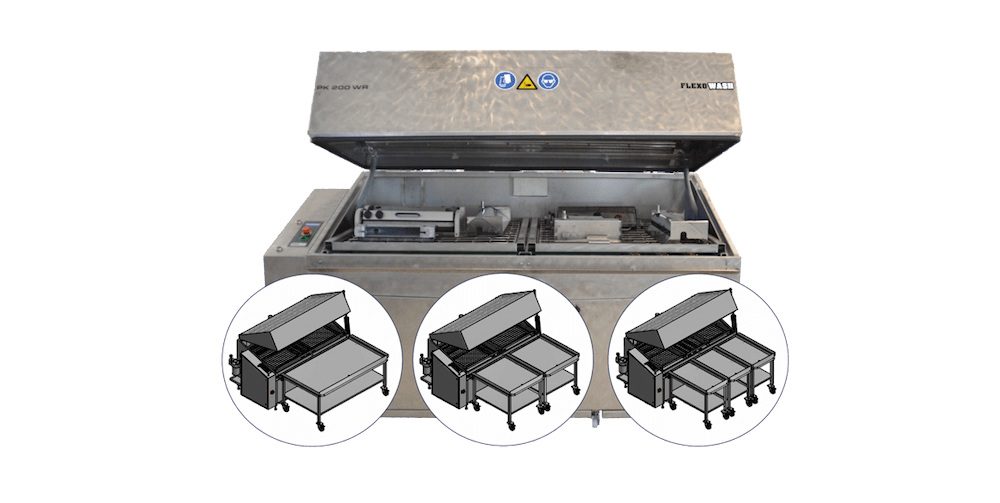

Parts washers for all needs

We supply parts washing equipment in all sizes for all segments of the labels industry. The Flexo Wash Parts Washers comes in many different models which each can be modified by combining the standard unit with one or more of the various options.

We have been leading experts in parts washing for 30 years and our large portfolio of units and options reflects the flexibility needed to meet all needs of the label industry.

Transform your liquid waste to solid powder waste for all narrow web parts washers with our Filtration Unit to reduce your liquid consumption.

PK ECO-series

Our low-cost PK ECO models have been developed to serve a broad part of the label industry.

The PK ECO-product line are fully automatic units designed to clean all kinds of parts.

The machines are controlled by a microprocessor, where it is easy to set the different programs such as wash time.

All models can be tailormade with holders for chambers securing the best washing result for your specific chambers.

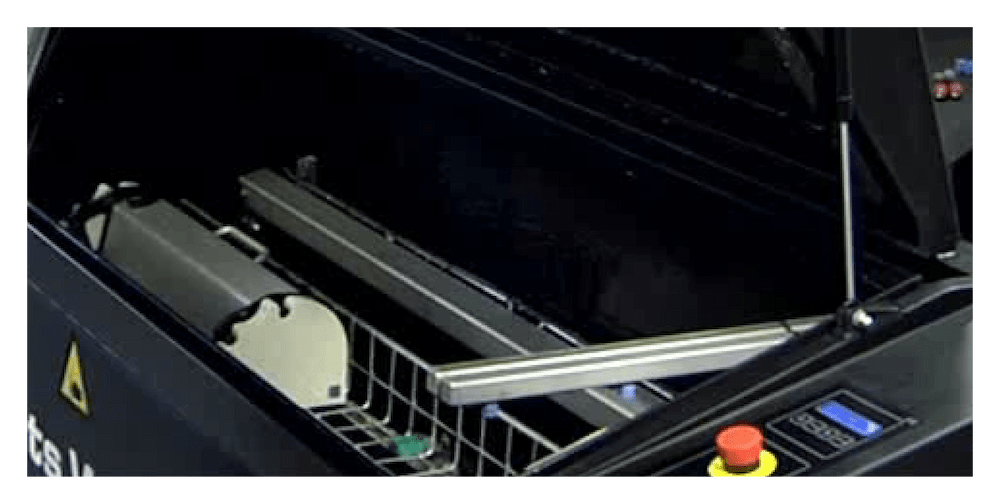

PK TopLoad

If your needs require a larger wash area than the PK ECO-series can provide, a PK TopLoad is your top choice.

The stainless-steel units also come with a custom-built wash area solution.

In the PK TopLoads the handling of the parts is made more accessible with slide-in grid, which means that the back grid can be slid to the front of the machine for easier mounting of parts.

PK TrolleyLoad

The PK TrolleyLoad provides with its trolleys an even easier handling of your press parts. Simply place the press parts on the trolley at the press.

Drive the trolley to the washing machine and push the grid into the machine. It is possible to wash doctor blade chambers, ink trays and other removable press parts.

This stainless-steel unit also comes with a custom-built wash area solution.

How does it work?

The PK Parts Washers work with environmentally friendly cleaning liquid, which is specially made for cleaning different types of ink.

The liquid from the high-pressure wash is automatically led directly to the drain, to a tank for re-use or to one of our liquid treatment units where the ink particles can be separated from the liquid making it possible to re-use the liquid for a higher number of cleaning cycles.

Liquid is sprayed onto the parts by nozzles placed below and above the grid/holders.

At the end of the wash cycle the cleaning liquid is drained back to the tank for re-use.

Before being ready for re-use the liquid is re-circulated through a filter.

The parts are rinsed with water or the same liquid as for wash, leaving the parts ready for immediate use.

Upon completion of the washing cycle the machine automatically stops and the lid is opened leaving the parts to dry.

In the PK ECO-units the lid should be opened manually.