Gentle flexo plate cleaner

The fully automatic flexo plate cleaning machine are designed to wash flexographic polymer plates and letterpress plates very gently. This leaves them 100% clean and dry, ready for immediate reuse or storage handling. Our innovative flexo plate cleaner ensures optimal cleanliness and efficiency in your plate washing process.

Eco-friendly cleaning liquids

After the print job, all plates are placed on the conveyor belt, which automatically takes them through the entire wash process. Utilizing the eco-friendly cleaning liquids from Flexo Wash, including our specially formulated solutions for flexo stereo cleaning, the plate washers efficiently remove different types of inks from the plates in only a few minutes. This ensures a quick turnaround for your printing needs with minimal downtime.

The machines are made of stainless steel and other highly resistant quality materials, including our top-notch plate cleaning machine and plate cleaner machine, ensuring a long lifetime of the product and a very low degree of maintenance.

Download product catalogue:

Fill out the form

To download our brochures and catalogs

Manual or automated plate cleaning?

Damaged plates due to improper cleaning is an expensive and critical factor in the printing industry. How do you choose the correct cleaning method?

Cleaning plates properly and in a gentle and safe way is essential. With unclean or broken plates you will have quality issues with your print.

But how to choose between manual cleaning or an automated cleaning system?

Learn about the difference, pros and cons of each system and how you choose the right solution for you in our "Manual or automated plate cleaning?" video. Download the guide to learn even more!

Plate washers for all needs

Explore our comprehensive range of plate washing equipment tailored for all segments of the labels and flexo industries. The Flexo Wash automatic plate washer comes in many different models. Our range of models cover plate widths from 45 cm up to 180 cm.

All units are available as both

- WRO-version: Fresh water

- WR-version: Water from the closed-loop wash tank

Transform your liquid waste to solid powder waste for all narrow web parts washers with our Filtration Unit to reduce your liquid consumption.

How does it work?

The plate washers from Flexo Wash have a two-stage Wash & Rinse cleaning process, where the first stage is for cleaning and the second stage is for rinsing.

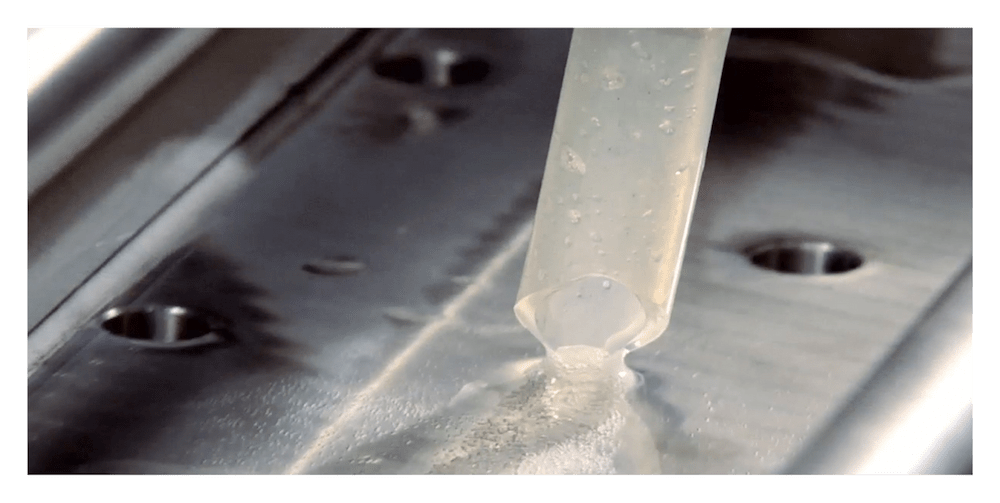

Easy loading of the plate by the conveyer belt. Cleaning liquid is sprayed on to the plate.

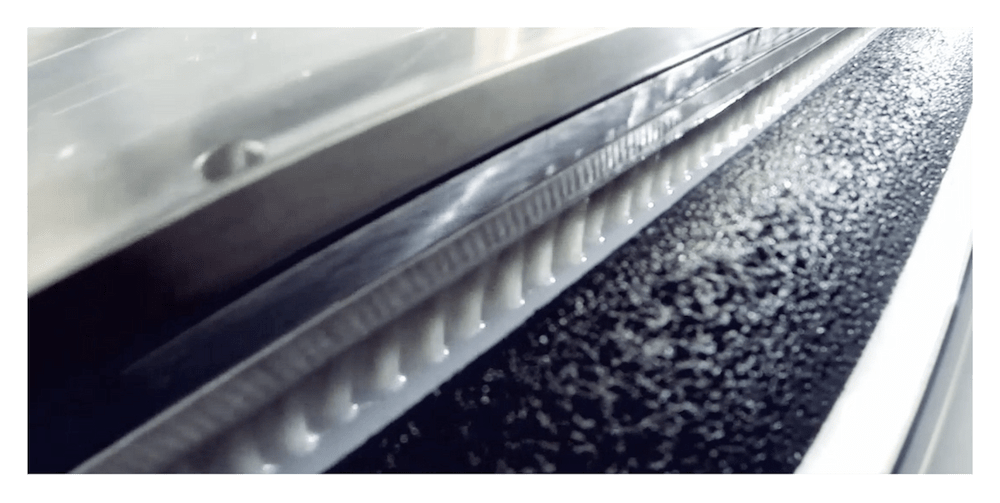

Gentle washing and cleaning of the plate by oscillating soft brushes.

Cleaning liquids are re-circulated and drained back to the tank for re-use.

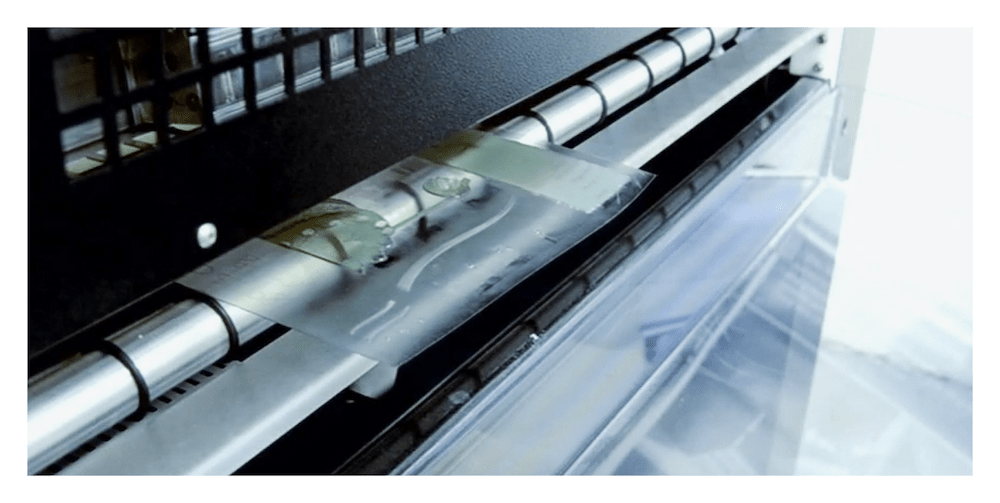

The rinsing of the plate is done by water to remove the remaining ink and cleaning liquid residues.

After the rinsing process, the plates are dried in two steps:

- Sponge roll

- Warm air knife