Daily deep cleaning of your aniloxes

The fully automatic anilox cleaners are designed to deep clean/restore anilox rolls or sleeves of all sizes. In other words, it is also a very good tool for the daily washing and maintenance of aniloxes.

Quick & gentle cleaning process

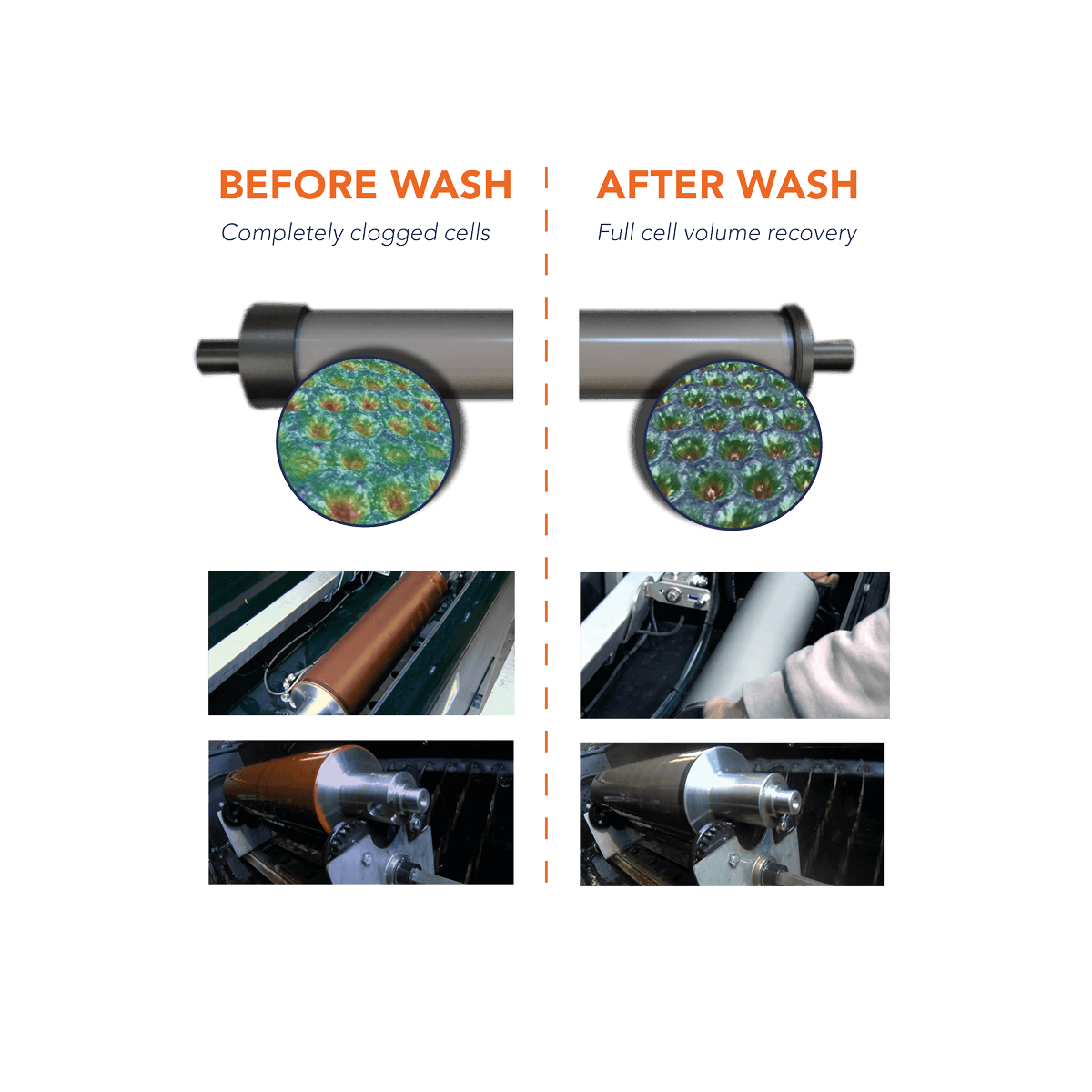

This Flexo Wash system, an advanced anilox cleaning machine, is based on liquid and high-pressure water. Therefore, the system is effective even for high-line aniloxes. The quick and gentle cleaning process leaves the aniloxes totally clean and ready for immediate use after just 10-20 minutes of cleaning, without causing any wear or tear to the anilox.

This makes it possible to keep your aniloxes totally clean at all times, ensuring high and consistent print quality and a long lifetime of the aniloxes.

Download product catalogues for:

Fill out the from

To download our brochures and catalogs

Anilox cleaners for all needs

We supply anilox cleaning equipment in all sizes for both the label and larger flexographic industry. The Flexo Wash Anilox Cleaners, including anilox cleaning machines and anilox roll cleaners, come in many different models, each of which can be modified by combining the standard unit with one or more of the various options. We have been leading experts in anilox cleaning, anilox roller cleaning chemicals, and anilox cleaning machines for 30 years, and our large portfolio of units and options reflects the flexibility needed to meet all the needs of the label and flexographic industries.

REPLACE THE CONNECTION TO FRESH WATER SUPPLY AND DRAINAGE FOR ALL ANILOX CLEANING UNITS WITH OUR RECIRCULATION SYSTEM, providing an environmentally friendly anilox cleaning solution and helping to reduce your water consumption.

FW Handy-series

Our low-cost FW Handy models have been developed to serve a broad part of the label industry.

The FW Handy-product line are fully automatic units designed to deep clean/restore anilox rolls and print sleeves of all sizes and providing you with a very good and cost-efficient tool for the daily washing and maintenance of aniloxes etc.

Depending on your specific aniloxes you will find a FW Handy Anilox Cleaner that will fit your needs.

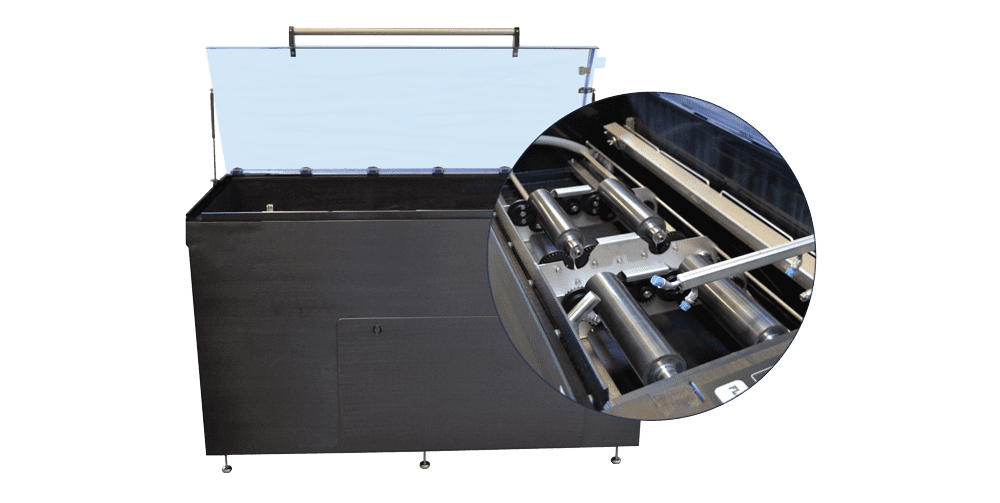

.NXT Generation

With the .NXT units we presents a new generation of anilox cleaning machines. All are produced with the .NXT features which means easier handling, improved technology & focus on sustainable solutions.

Enhanced qualities of the .NXT units:

- Better & faster drainage

- Automatic liquid filling

- Easy access pull-out tank

- Liquid level indicator

- Improved lid design

- Easy adjustment of traction stations

FW PLC-SERIES

All larger FW Anilox Cleaners are equipped with a PLC control, which enables easy change of the various program settings e.g. washing time, rotation speed and temperature. It is also possible to enter an alarm log.

The PLC Anilox Cleaners are designed to clean larger and heavier rolls and sleeves. They can all be adapted to fit your specific needs by for example adding an extra traction system to clean more aniloxes per wash, an adaptor to clean sleeves safely or reinforcing the machine to clean even heavier rolls.

How does it work with the anilox cleaner?

The Flexo Wash Anilox Cleaners, including the anilox cleaning machine and anilox roll cleaner, work with environmentally friendly cleaning liquid, including anilox roller cleaning chemicals, which is specially made for deep cleaning of aniloxes used with all types of ink. The water from the high-pressure rinse, facilitated by the anilox cleaner machine, is automatically led directly to the drain, to a tank for re-use, or to one of our water treatment units, ensuring an efficient anilox cleaning process.

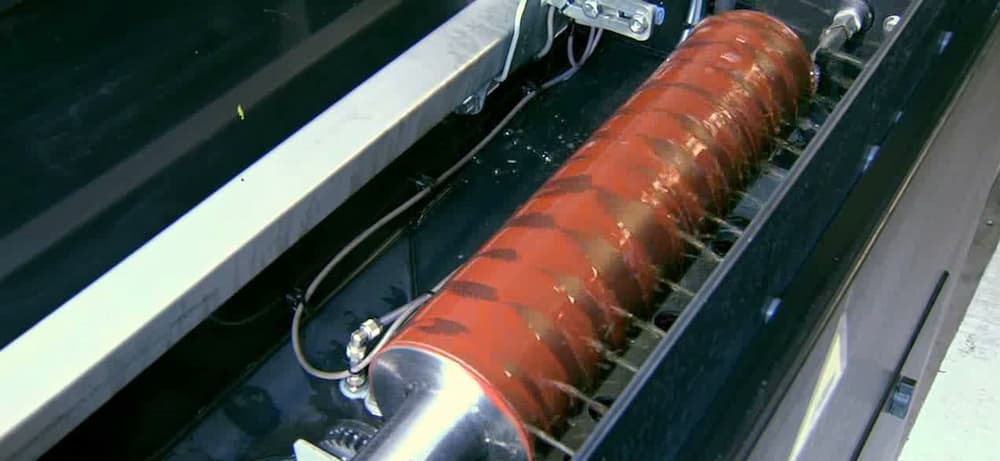

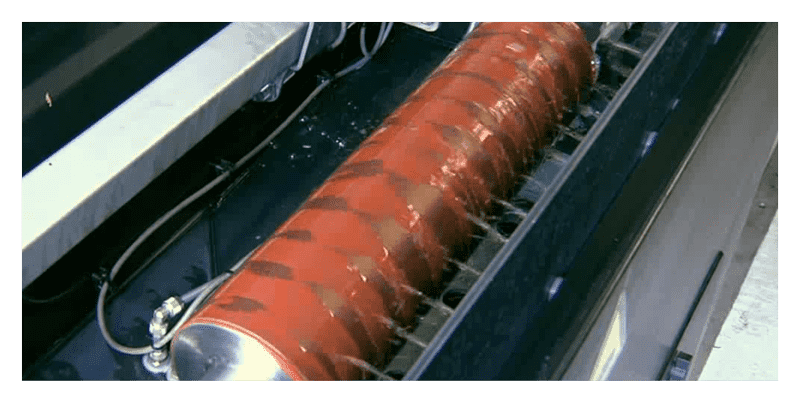

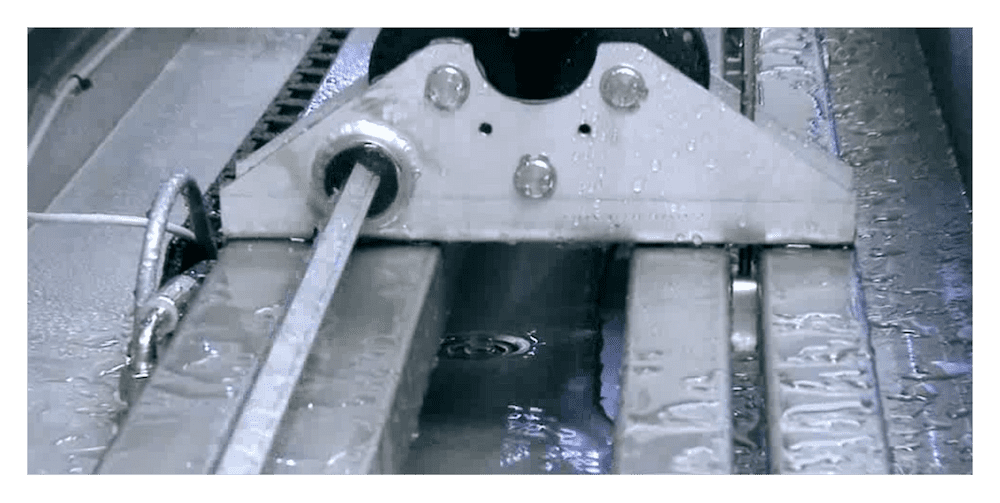

The anilox rotates while heated liquid is sprayed onto the surface and enables easy removal of the ink from the anilox cells.

Average washing time is 5-20 minutes.

Drain time is 2-3 minutes.

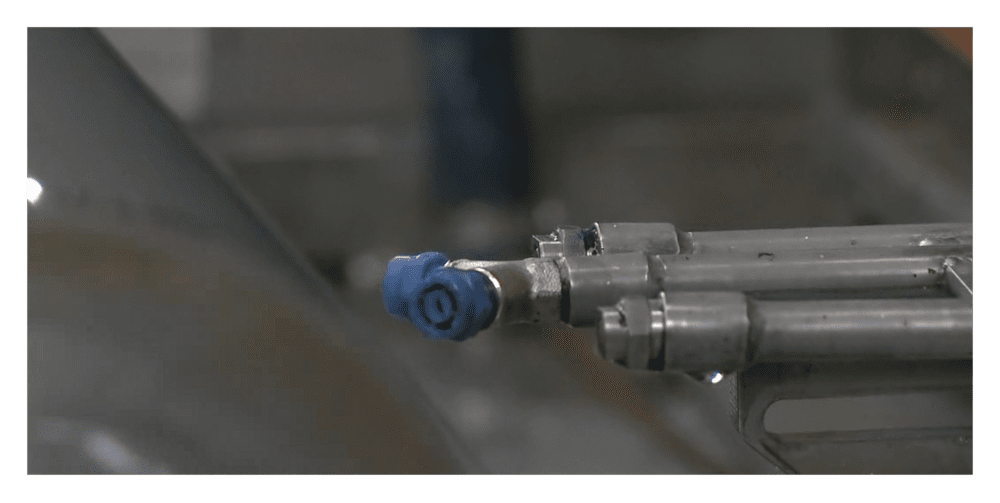

High pressure adjustable water nozzles complete the cleaning process and removes any remaining ink particles and cleaning liquid.

Rinse cycle is approx. 2-3 minutes.

High pressure air drying completes the cleaning process leaving the anilox ready for immediate use or storage.

Duration is 1-3 minutes, depending on roll length.

Because of the anilox cleaner the condition of our aniloxes is always consistent. It is important to always have clean aniloxes to keep the same printing quality. And that we have!