The anilox is the heart of the flexo process, and it is frustrating when you once again have to shut down your production and wait for the anilox to be cleaned or figure out halfway through a project that the anilox was not clean after all – you are losing money and valuable time.

But wouldn’t it be great if you could clean your aniloxes faster and consistently? Thereby, having no downtime, no lost projects and no losing money! Maybe even increase your production limits. The industry has changed and is moving faster. Our Anilox expert Daniel Yjord explains why:

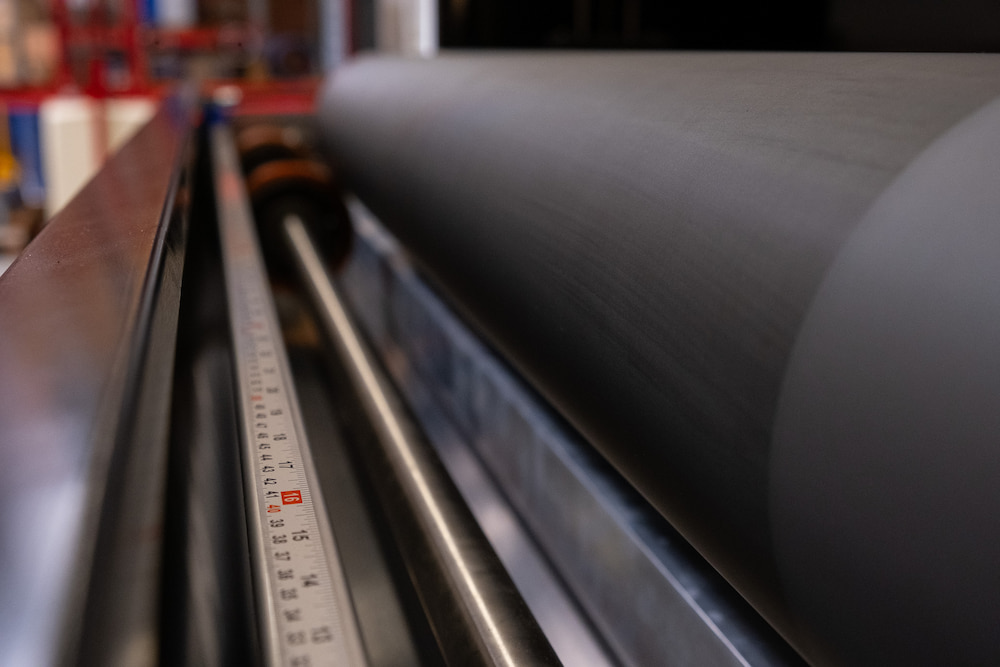

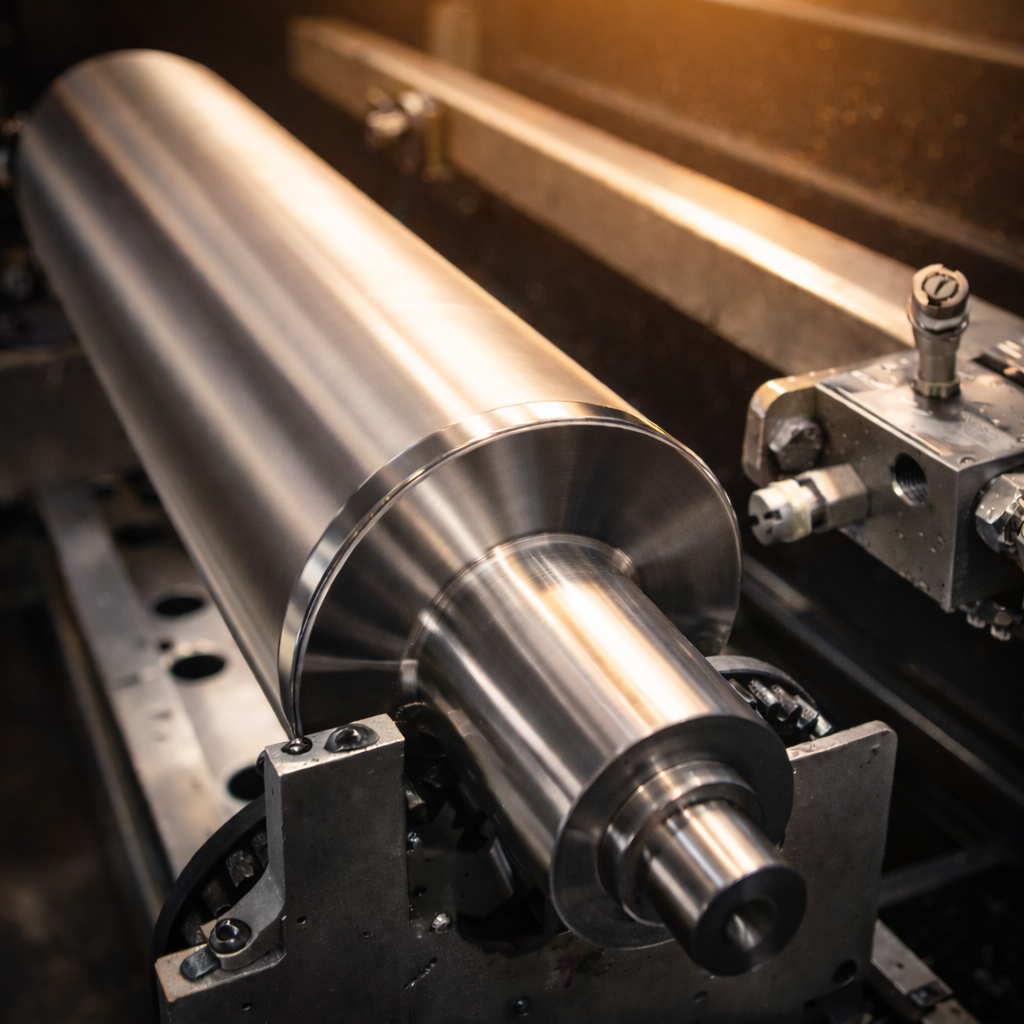

“To be honest the anilox is the heart of the press, and you need to do regular check-ups on that important part of the machine. The whole flexo printing technology has developed tremendously over the past few decades. And brand owners have an increasingly high demand for quality print on the labels, and the sleeves that go onto their products on the shelves. Anilox technology has of course also developed, and today we are seeing anilox rolls with higher density, and thinner cell walls, and therefore it is important that there is a careful cleaning of those aniloxes. Only that way you can control the critical points in printing, which are colour density and colour matching.”

Good printing quality is key for your business!

We have already mentioned some of the benefits of clean aniloxes and some of the consequences of dirty aniloxes but let me take it a step further!

Good printing quality is key for your business, but there are several things that can affect your production. Regarding an anilox it is very important that the cell volume of the anilox does not get reduced, so you have difficulties transferring the right amount of ink because that gives you poor colour densities, inadequate ink distribution, wasted ink and all in all just poor print quality. Without proper cleaning, you can be forced to replace an anilox much sooner, than if you have a consistently good cleaning.

But with one key investment in your production, you can turn it around and receive the benefits! All the issues mentioned above disappear and you get consistently high print quality. You minimize the waste of ink and substrate. There is less downtime, reduced labour cost and most importantly your anilox increases its lifetime and always has high cell volume.

To sum up, when you have proper cleaning of your aniloxes you save time, you save money, and you have the potential to earn more money. But if you save money, why doesn’t everybody have a cleaning machine? Daniel again explains:

“Some printers think this is an expensive piece of equipment, and maybe they were not given a proper return on investment calculation, showing the real cost of re-runs, waste and press downtime. Some people regard an anilox cleaner as a non-productive piece of equipment, but sometimes they forget that the overall performance of the machine depends on all the components working in unity to ensure the high-quality print including the anilox roll of course.”

Every case is unique – we know this at Flexo Wash because we have provided over 5000 cleaning units worldwide. It is very important to look at the number of aniloxes you clean daily because that is a key factor in calculating your ROI. Our agents at Flexo Wash can quickly and easily with just a few numbers from you make an estimated ROI to see if you can benefit from an automated cleaning solution from Flexo Wash.

How do you clean your aniloxes?

There are two methods for cleaning: manual cleaning and automated cleaning. The risks of manual cleaning often overshadow the benefits. Pads, abrasive cleaners, and brushes are losing their effectiveness in today’s deeper and smaller cells, but more importantly, these manual tools can cause damage to the expensive aniloxes. Furthermore, you should consider health and safety concerns derived from manual cleaning.

There are a lot of good systems available for the automated cleaning of aniloxes. The bigger start-up investment of one of these solutions will save money in the long run with less substrate used for the start-up of the press, less downtime on the press and reduction of labour costs. In other words, it will lower your quality cost and give you a higher output.

In most cases, Flexo Wash recommends a combination of both methods, where automated cleaning work as your daily deep clean and manual cleaning is a supplement to your automated workflow.

But before you go out and invest in an automated cleaning system ask yourself these questions:

Which ink/coating type is used?

→ Ink types can be difficult to remove, why it is an important factor to find the right solution.

What are the sizes of your aniloxes?

→ The anilox should be able to fit in a cleaning system - or maybe you need different sizes to fit in the same?

Which line count do the aniloxes have?

→ The fewer line counts the easier the cleaning. A higher line count requires more advanced cleaning methods.

Is your anilox inventory large or limited?

→ If you have a limited inventory available the cleaning time needs to be more effective.

When to clean?

One thing is how to clean your aniloxes but knowing how you clean your aniloxes is not everything. You also need to know when you should clean your aniloxes. Therefore, at Flexo Wash, we recommend that you set up a high-quality cleaning cycle, which also gives you more knowledge about how many projects your business can handle.

Make sure that your aniloxes are properly clean from day one. Increase the lifetime of a valuable investment for your business by making another investment in cleaning in due time. Clean after each job and before storage. Never leave an anilox lying around, because ink becomes more difficult to remove from the fine cells the longer the ink (or coating) dries in the cells.

Depending on the system you should deep clean your aniloxes more thoroughly once a week, besides keeping a daily cleaning cycle. However, some systems are gentle enough to allow you a daily deep cleaning.

It is all in the details

And we say this with care because there are a lot of details on an average anilox. Millions of tiny cells and sometimes much more! And you cannot check every little detail. Therefore, it is vital for your print business that you implement a cleaning system, which gives you a consistently high result and leaves you only to do quality check-ups.

You cannot monitor your whole cleaning process. Be smart and invest in a cleaning system you can trust for many years to come that lets you focus on getting quality prints out to more customers.

To learn more click here: Anilox cleaning by Flexo Wash

.jpg.jpg)