As printing jobs become shorter with more frequent changeovers, and quality demands continue to rise, your cleaning system isn’t just a support function, it’s a critical component of your production efficiency. The question isn’t whether you need effective cleaning, but whether your current setup is truly serving your business goals.

Here are five clear warning signs that it’s time to consider upgrading your cleaning system:

1. Increasing Downtime and Production Delays

If you’re spending more time cleaning than printing, it’s a clear indicator. Manual cleaning processes that take from 30-60 minutes per job change versus automated systems that clean in 10-15 minutes represent significant lost productivity. When operators are tied up with cleaning instead of focusing on press make-ready functions, you’re losing money.

2. Inconsistent Print Quality Issues

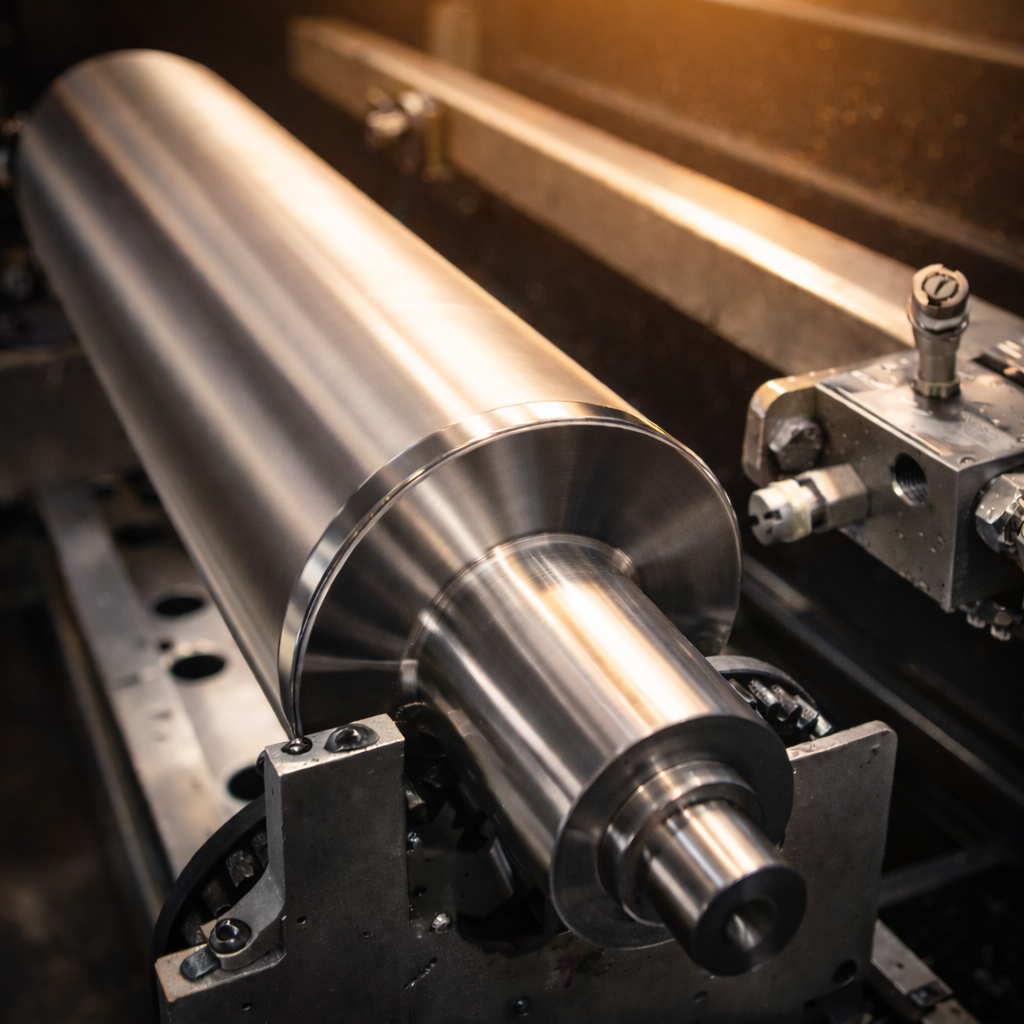

When anilox cells aren’t completely cleaned, you get inconsistent ink transfer, leading to print defects, colour variations, and customer complaints. If you’re experiencing reprints, waste, and quality issues, your cleaning system likely isn’t restoring your anilox cell volume to 100%.

3. Rising Operational Costs

Excessive consumption of cleaning liquids, increased waste disposal costs, or frequent replacement of damaged parts (especially anilox rollers) indicate inefficient cleaning. Modern systems with filtration and recirculation can reduce liquid consumption significantly while extending equipment life.

4. Safety and Environmental Compliance Concerns

If you’re still using manual solvent cleaning without proper ATEX rooms or struggling with environmental regulations regarding waste disposal and emissions, it’s time to consider safer alternatives like alkaline cleaning systems or closed-loop automated solvent cleaning and recovery.

5. Equipment Wear and Frequent Breakdowns

When your current cleaning equipment requires constant repairs, has outdated technology, or is badly maintained, and therefore can’t handle your current production volumes (like cleaning multiple cylinders per day), upgrading to modern, automated systems will improve reliability and efficiency.

The key is recognising that cleaning isn’t just a cost center, it’s critical to maintaining consistent print quality, high productivity, and a safe working environment.

Don’t Let Outdated Cleaning Slow You Down

Recognising these warning signs is the first step toward transforming your operation. Modern cleaning technology isn’t just about getting parts clean, it’s about creating a competitive advantage through faster changeovers, consistent quality, reduced waste, and improved safety.

The printing industry continues to evolve with shorter runs, tighter deadlines, and higher quality expectations. Your cleaning system should be an enabler of this evolution, not an obstacle. If you’re experiencing any of these five signs, it’s time to explore how advanced cleaning solutions can unlock your operation’s full potential.

Remember: cleaning isn’t just a cost center, it’s critical to maintaining consistent print quality, high productivity, and a safe working environment. The question isn’t whether you can afford to upgrade, but whether you can afford not to.

Ready to discuss how modern cleaning technology can transform your operation? Contact your local Flexo Wash representative to explore solutions tailored to your specific needs.