Introduction

If you're experiencing the hassle and mess of dirty press parts in your print business, automated cleaning can provide a solution. Dirty press parts have negative impacts on print quality, efficiency, and safety, leading to longer downtime, inefficient cleaning, and taking up valuable space in your facility. However, with automated cleaning, you can enjoy tailored washing units from Flexo Wash that ensure dynamic liquid flow and higher pressure for improved wash results.

Automated cleaning can save you time and money in the long run by reducing the need for manual labor, extending the lifespan of your press parts, and improving workflow and productivity. Clean press parts are also vital for improving print quality and customer satisfaction, as well as providing a safer working environment for your employees.

The problem with dirty press parts

Dirty press parts can pose significant problems for print businesses. First and foremost, they can lead to poor print quality, resulting in dissatisfied customers and lost business. Additionally, dirty press parts can lead to longer downtime as manual cleaning takes more time and effort. This can be especially detrimental to businesses with tight deadlines and high-volume workloads. Furthermore, dirty press parts can take up valuable space in your facility, leading to inefficiencies and decreased productivity.

The benefits of automated cleaning

Automated cleaning can solve the problems of dirty press parts by providing tailored washing units that are designed to meet the specific needs of your print business. With automated cleaning, you can enjoy a more efficient cleaning process that reduces downtime and eliminates the need for manual labor. The dynamic liquid flow and higher pressure of the moving nozzle arm ensure that your press parts are thoroughly cleaned without the need for recleaning. Additionally, automated cleaning takes up less space in your facility, providing you with more room to focus on other important aspects of your print business. By implementing automated cleaning in your print shop, you can improve your workflow, increase productivity, and ultimately provide your customers with better quality prints.

How Automated Cleaning Works

Automated cleaning can revolutionize your print business by eliminating the hassle of manual cleaning and providing tailored washing units designed to meet your specific needs. With automated cleaning, you can experience a more efficient and consistent cleaning process that is faster, safer, and ensures spotless press parts ready for use.

Moreover, automated cleaning is a cost-effective solution that saves you time and money in the long run. By reducing the need for manual labor, you can cut down on labor costs, while extending the lifespan of your press parts helps you save on replacement costs. Plus, automated cleaning takes up less space in your facility, providing you with more room to focus on other essential aspects of your print business.

Improved efficiency is another benefit of automated cleaning. With reduced downtime caused by manual cleaning, you can increase productivity and workflow, ultimately providing your customers with better quality prints. Consistent cleaning quality is also ensured with automated cleaning, delivering high-quality results every time.

Clean press parts are crucial for improving print quality, customer satisfaction, and providing a safer working environment for your employees. By implementing automated cleaning of press parts in your print business, you can transform your operations and experience the benefits firsthand.

The technology behind automated liquid cleaning

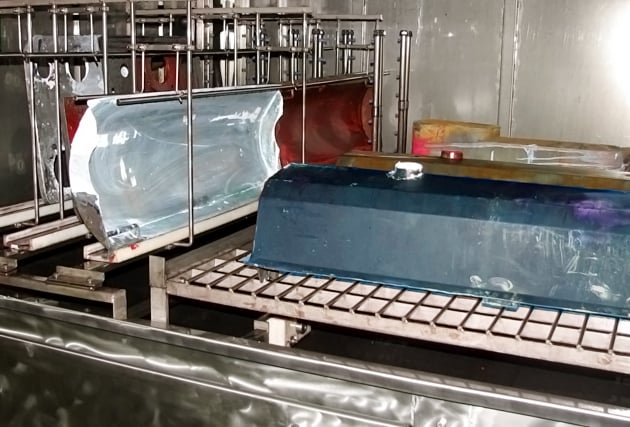

The liquid cleaning system used in automated cleaning units from Flexo Wash is a highly effective method for removing ink, varnish, and other contaminants from press parts. The cleaning solution is a carefully formulated blend of chemicals and detergents that are tailored to meet the specific needs of your print business.

During the cleaning process, the solution is pumped through the moving nozzle arm, which ensures a dynamic flow and higher pressure for improved wash results. The solution is then sprayed onto the press parts, breaking down and dissolving any contaminants on the surface. The cleaning solution is then rinsed off with water, leaving the press parts spotless and ready for use.

The liquid cleaning system is highly efficient and provides consistent cleaning results every time. The system is also environmentally friendly, as the cleaning solution is biodegradable and does not contain any harsh chemicals that can be harmful to the environment.

Overall, the liquid cleaning system used in automated cleaning units is a highly effective and efficient method for cleaning press parts. It saves time and money by eliminating the need for manual labor and provides consistent, high-quality results every time.

The benefits of automated liquid cleaning over manual cleaning

Automated cleaning is the way to go if you want to revolutionize your print business. It eliminates the hassle of manual cleaning and provides tailored washing units designed to meet your specific needs. By reducing the need for manual labor, you can cut down on labor costs, while extending the lifespan of your press parts helps you save on replacement costs. Moreover, automated cleaning takes up less space in your facility, providing you with more room to focus on other essential aspects of your print business.

Improved efficiency is another benefit of automated cleaning. With reduced downtime caused by manual cleaning, you can increase productivity and workflow, ultimately providing your customers with better quality prints. Consistent cleaning quality is also ensured with automated cleaning, delivering high-quality results every time. Clean press parts are crucial for improving print quality, customer satisfaction, and providing a safer working environment for your employees.

By implementing automated cleaning of press parts in your print business, you can transform your operations and experience the benefits firsthand.

Improved Efficiency with Automated Cleaning

See how automated cleaning can improve your print shop's workflow and productivity.

Automated cleaning is a game-changer for print businesses looking to improve their workflow and productivity. With reduced downtime caused by manual cleaning, you can increase your output and meet tight deadlines more efficiently. By streamlining the cleaning process and eliminating the need for manual labor, you can focus on other essential aspects of your print business, such as customer service and marketing.

Moreover, automated cleaning ensures consistent cleaning quality every time. This means that your press parts are cleaned thoroughly and spotless, without the need for recleaning or rework. Consistent quality also means that you can exceed your customers' expectations and improve their satisfaction, leading to repeat business and referrals.

In conclusion, automated cleaning is an effective solution for print businesses looking to improve their workflow and productivity while maintaining high-quality standards. By implementing automated cleaning of press parts, you can transform your operations and experience the benefits firsthand.

Reduced downtime

Automated cleaning can significantly reduce downtime caused by manual cleaning in your print business. With manual cleaning, the process can be time-consuming, and your employees may need to take breaks between cleaning sessions. This can lead to longer downtime and decreased productivity. However, with automated cleaning, you can eliminate the need for manual labor and streamline the cleaning process. The tailored washing units ensure that press parts are cleaned thoroughly and quickly without the need for recleaning or rework. This means that your employees can focus on other essential tasks, and you can meet tight deadlines more efficiently.