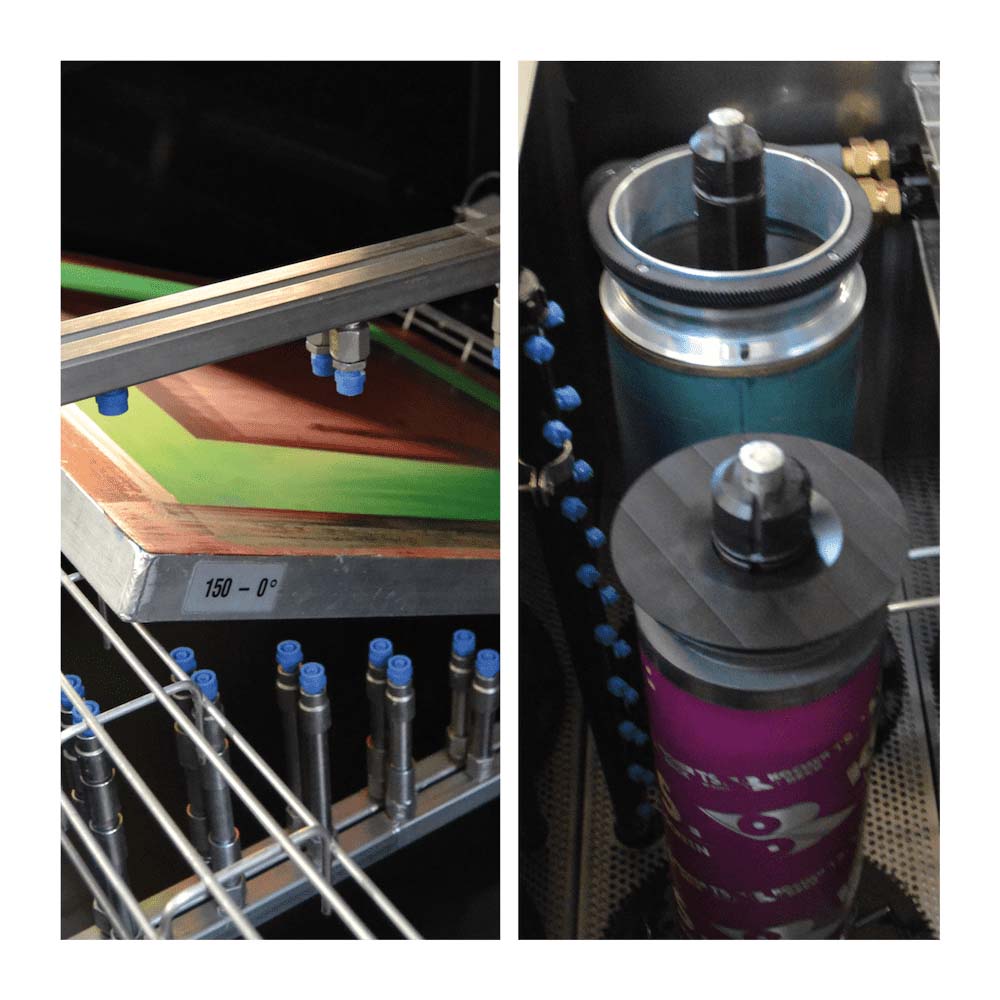

Cleaning in a Flexo Wash screen washer results in reduced downtime, consistent print quality and a safe and healthy cleaning and working environment. The delicate cylinder screens can be difficult to handle properly in an environment where time is money. Therefore, with a cleaning unit broken screens is very unlikely to happen.

TAKE CARE OF YOUR SCREENS

- Clean and dry screens fast

- Quick and gentle wash operation

- Timer-controlled washing time - can be adjusted from 1-100 minutes

- Limited labor and minimal maintenance.

The PK 92-series requires only 30L of cleaning solution which is circulated by means of an air powered diaphragm pump. The liquid is filtered and recirculated in a closed-circuit system without any waste to the environment.

You can easily set the washing time with the integrated timer. The screen is sprayed with liquid from both the inside and outside to ensure safe and thorough cleaning. After cleaning the screen can be moved to the integrated chamber for drying. If the screen needs to be rinsed with alcohol an external dip tank can be purchased.

The cleaning liquid used is our eco-friendly FW86500, which is guaranteed harmless to your screens. The washing time is controlled by a timer, adjustable from 1 to 100 minutes. Normal washing time is approx. 10 minutes. Learn more about our liquids here.

Flexo Wash supplies washing units for two types of screens: