The Flexo Wash ATEX cleaning machine is prepared during production to handle the strong solvents and thoroughly checked before it is sent to your facilities. However, before you can operate your cleaning machine you need to have a secured ATEX-zone to completely neutralize the risk of explosions or fire in your production.

Learn more about our parts washing units here.

ATEX-Zone regulations

Cleaning with solvents can be dangerous so to run the fully automatic cleaning unit you need a secure ATEX-zones. Flexo Wash delivers washing equipment according to the ATEX directive 2014/34/EU intended for use in potentially explosive atmospheres.

At Flexo Wash, we collaborate with notified bodies for approval of the equipment, ensuring that each unit is safe, EEX-proof according to the ATEX standard, and certified by ExVeritas.

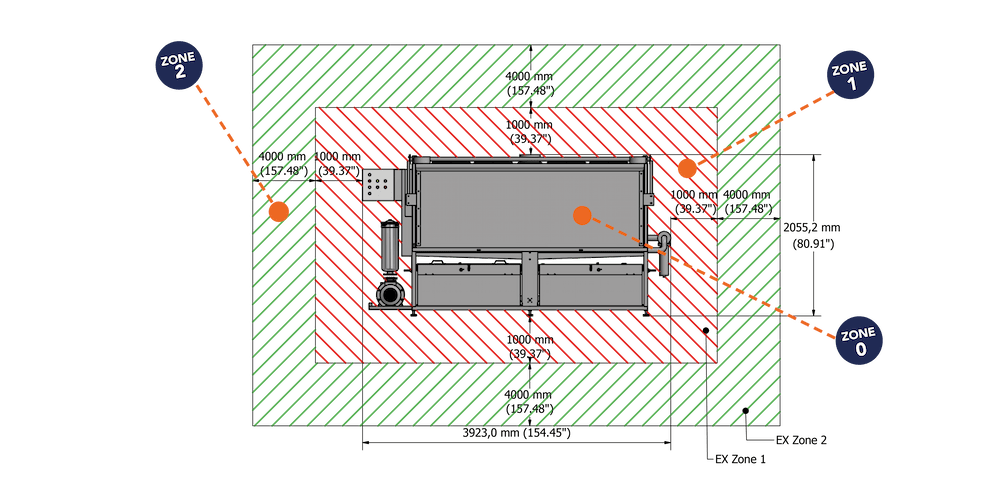

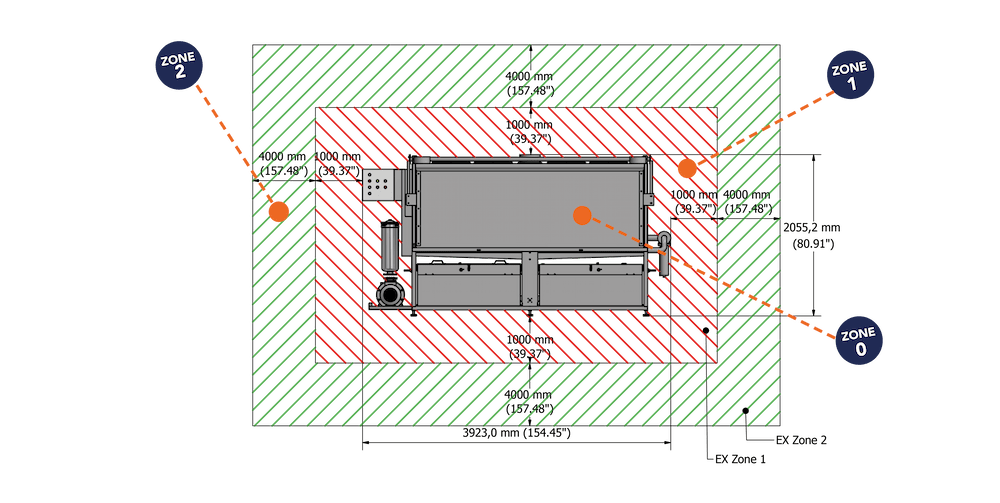

The ATEX zone is divided into three categories depending on the number of hours of explosive atmosphere per year in each zone.

ZONE 0 = CATEGORY I:

Explosive atmosphere is continuously present for long periods. Inside the washing unit and tanks the unit will have ATEX zone 0. As zone 0 is inside the machine the responsibility is mainly carried by the cleaning machine manufacturer.

ZONE 1 = CATEGORY II:

Between 10 and 100 hours of explosive atmosphere per year. Around the unit will be ATEX zone 1.

ZONE 2 = CATEGORY III:

Less than 10 hours of explosive atmosphere per year. Zone 2 is often referred to as the remotely hazardous area. Electrical fittings & bulbs placed in zone 0-2 must be thoroughly checked and you must regularly ensure that the electricals present in the area are fully ATEX certified. You can test your ATEX knowledge in our ATEX quiz.

Outside of your designated ATEX room, there must be a control box for your unit and there should also be a control box next to the ATEX parts washer. Always be aware of the ATEX standard and the minimum safety distance to the unit.

Other mechanical equipment also needs to be approved for operating in a zone ATEX environment (zone 2)

The air conditioning in the ATEX area must follow clearly defined standards to make sure that the ventilation process is secure, so the solvent fumes are led to an RTO or open air.

Worldwide service

Creating an zone ATEX is very simple. The regulations and requirements are very clear. At Flexo Wash, we will always provide you with the service you need anywhere in the world, both on-site and virtually.

If you are cleaning with solvents and looking for help with setting up an ATEX zone, we will also provide you with the information you need to complete the zone in time for your new cleaning unit to arrive at your production facilities.