Regardless of the type of ink or cleaning method you prefer, Flexo Wash offers a wide range of units that all have one thing in common - they can clean your cylinders in just 20 minutes.

Non-solvent cleaning: FW Gravure series

All larger FW Cylinder Cleaners are equipped with a PLC control, which enables easy change of the various program settings for example rotation speed, temperature and washing time – which can be 20 minutes or less depending on your solution.

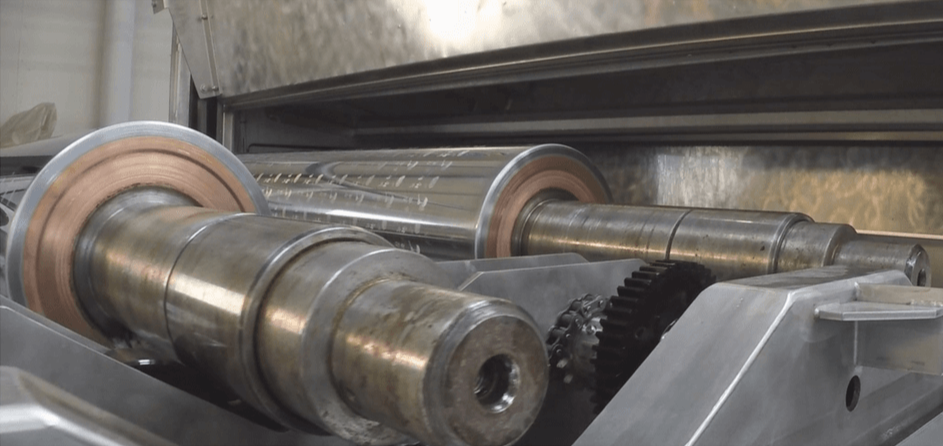

The FW 3000-4500 Cylinder Cleaners are designed to clean larger and heavier rolls and sleeves. They can all be adapted to fit your specific needs by for example adding an extra traction system to clean more than one cylinder per wash or reinforcing the machine to clean heavier rolls.

The FW 2000-2- & 3000-2 Cylinder Cleaners are designed to clean two cylinders per wash. By adding an extra traction system these units can wash as many as four cylinders per wash.

Finally, the FW 3000-4500 XL models are designed to hold an even larger cylinder diameter than the FW 3000-4000 standard units.

Solvent-cleaning: GCC 2300 ATEX-series

The Gravure Cylinder Cleaner 2300 ATEX is made for cleaning of gravure cylinders with solvents. It is safe to use and gentle on the cylinders, so you can clean the cylinders as often as you want.

The system is based on solvents sprayed on the cylinder and the cleaning process leaves the cylinders clean and ready for immediate reuse or storage without any damage. The system is effective for all types of cylinders.

The Gravure Cylinder Cleaner 2300 ATEX can be equipped with oscillating end face brushes.

The GCC 2300 ATEX comes in two variants:

- GCC 2300-1 ATEX for cleaning 1 cylinder per wash cycle

- GCC 2300-2 ATEX for cleaning 2 cylinders per wash cycle

Multi Cylinder cleaning

The Multi Cylinder Cleaner can clean cylinders fast using a conveyer belt technology and one cylinder can pass through the unit in just 5-20 minutes depending on your solution. The modular concept makes it possible to increase the cleaning capacity over time, by simply adding for example an extra washing or rinsing module station.

The cleaning unit cleans by using eco-friendly cleaning liquid, afterwards rinsing the cylinders with water at high pressure and finally an air stream removes excess water.

The cylinders can be transported from the printing machine on a special designed trolley with a cylinder carriage. The carriage is loaded from the trolley into the loading station and automatically transported through the cleaning process.