Upgrade to the Future with Laser Anilox Cleaner

Discover a waste-free and sustainable solution with the FW LASER Anilox Cleaner. This cutting-edge technology ensures precise anilox cleaning, effortlessly removing dried ink and residues. Benefit from the power of laser precision without the need for water supply, drain, or additional safety equipment.

Focus on Flexibility with Anilox Laser Cleaning

Experience unparalleled flexibility in anilox cleaning with the FW Anilox Laser Cleaner. The FW 2000 - 3000 model allows you to efficiently clean several narrow web rolls or a combination of narrow and wide web rolls and sleeves in ONE machine.

For more compact needs, the FW 850-series lets you clean up to two narrow web rolls in a single cycle.

This waste-free and sustainable cleaning method eliminates liquid handling and consumption, ensuring an environmentally friendly solution.

Download product catalogue:

Fill out the form

To download our brochures and catalogs

Embrace the technology in anilox laser cleaning

Step into the future of anilox care with the FW Laser Anilox Cleaning units. Designed with cutting-edge technology, these units prioritize high protection for your anilox. Easy handling and the latest software solutions make the cleaning process seamless. At Flexo Wash, we are experts in anilox cleaning, and our commitment to excellence drives the innovation behind the laser-series.

Read more about the special features below.

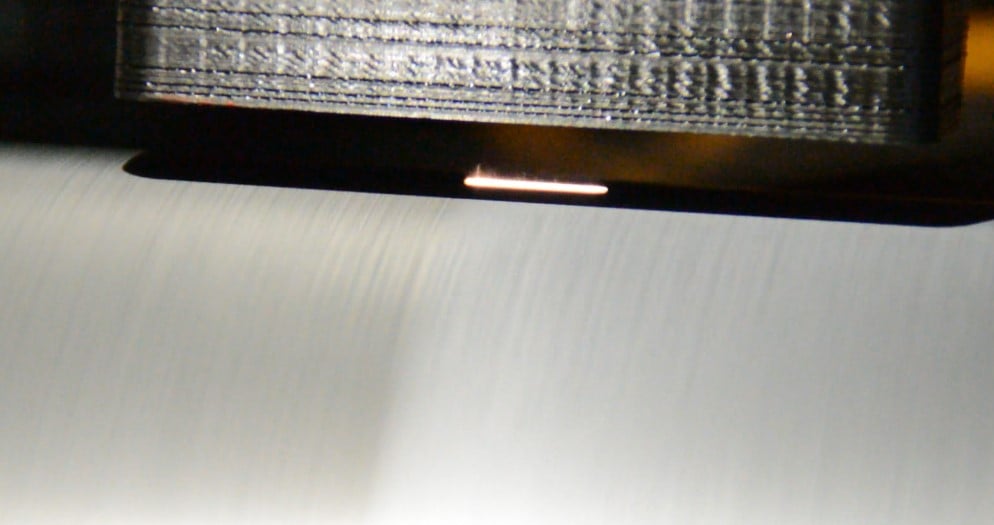

CLASS 1 LASER SYSTEM WITH AUTO FOCUS

Safe under all conditions of normal use - no need for safety goggles or other safety equipment.

The laser is automatically adjusted to the size of the anilox roll making the process fast, user friendly and safe.

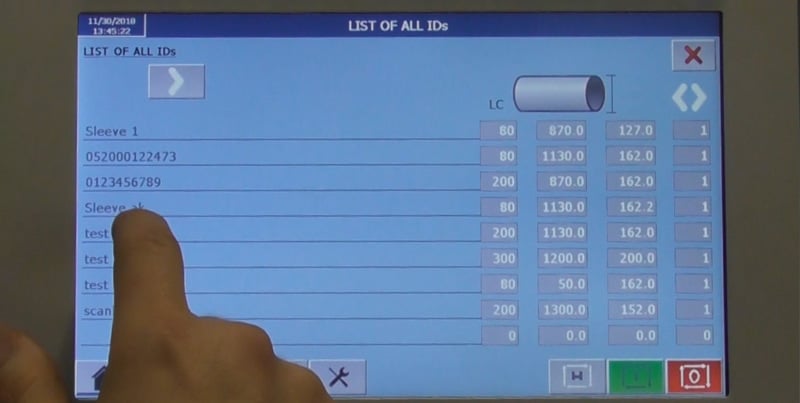

ANILOX DATABASE WITH EVENT LOG

Each anilox and its cleaning log is registered ensuring a well- documented cleaning log of every anilox.

Data regarding cleaning and alarms can be accessed by technicians via LAN connection.

EASY HANDLING CONCEPT

On the FW 2000 - 3000 unit the electrically driven drawer ensures easy loading and high degree of protection of the anilox.

Same concept has been transferred to the FW 850-series where the slide-in rack guarantees safe and easy handling during loading and unloading.

BARCODE / RFID SCANNER

Handheld barcode / RFID reader to identify the anilox type and identity can be added to the unit.

However, this option requires that the anilox is manufactured with a unique RFID tag.

The reader assists the operator in setting the correct parameters for the specific roll.

We are very satisfied with the cleaning results and the easy handling of the aniloxes. We tested another laser system, but it damaged the rolls. With the Flexo Wash unit we have no issues at all!