Cleaning multiple cylinders at once

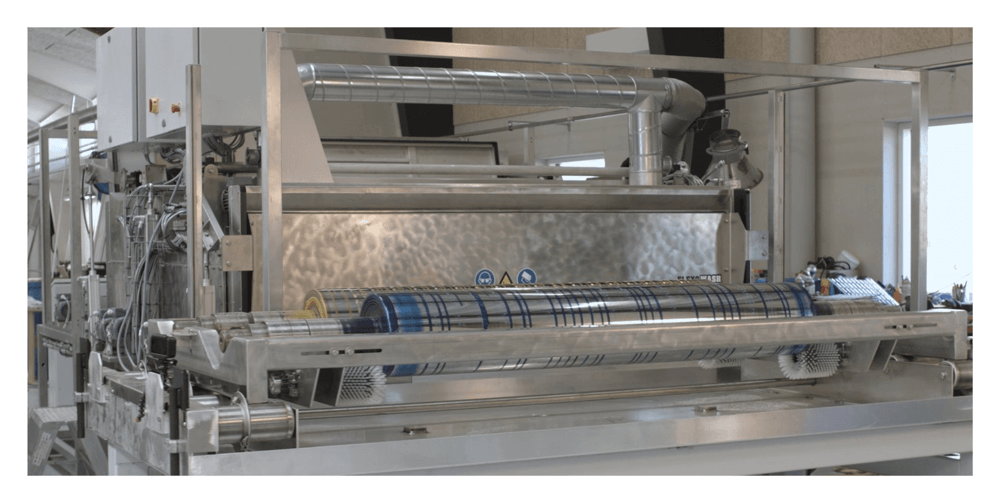

The demand for clean cylinders and automated time saving solutions is a constant battle for the print industry. With the MCC system it has never been easier. Using a non-solvent system, the Multi Cylinder Cleaner cleans and rinses cylinders, representing a more economical yet sustainable cleaning solution.

Eco-friendly cleaning & easy handling

The Multi Cylinder Cleaner is designed to clean a larger number of rotogravure cylinders and it is built after a modular concept in separate sections. This makes it possible to increase the cleaning capacity over time, by simply adding for example an extra washing or rinsing module station.

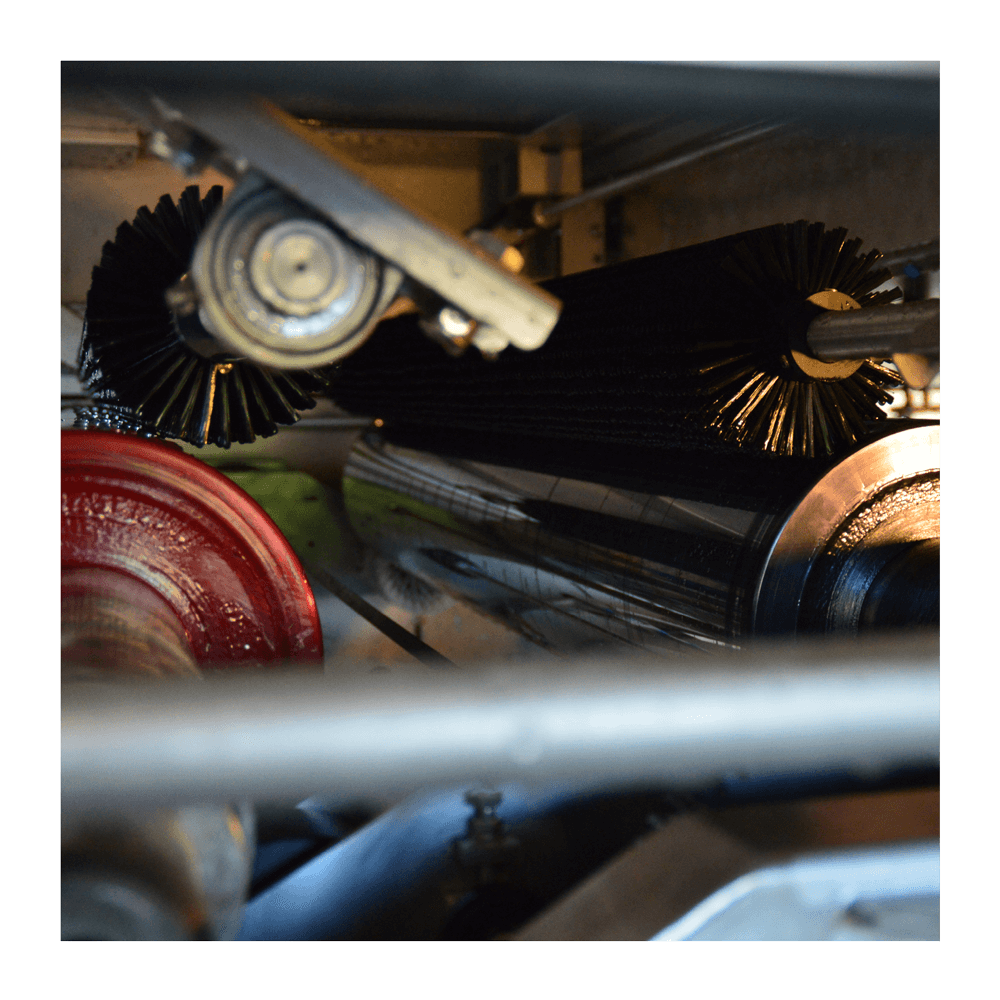

The cleaning unit cleans by using eco-friendly cleaning liquid, afterwards rinsing the cylinders with water at high pressure and finally an air stream removes excess water.

The cylinders can be transported from the printing machine on a special designed trolley with a cylinder carriage. The carriage is loaded from the trolley into the loading station and automatically transported through the cleaning process.

Download product catalogue:

Fill out the form

To download our brochures and catalogs

Your needs - your own configuration

Due to the modular construction of the MCC, the system can be configured according to your needs. This gives you the possibility to create the configuration best fitting your specific needs. Below you will find three examples of different configurations for illustratory purposes only - your induvidual configuration depends on cleaning volume, handling and level of automatisation.

To reduce your consumption of non-solvent liquids connect the MCC unit with our Sedimentation tank.

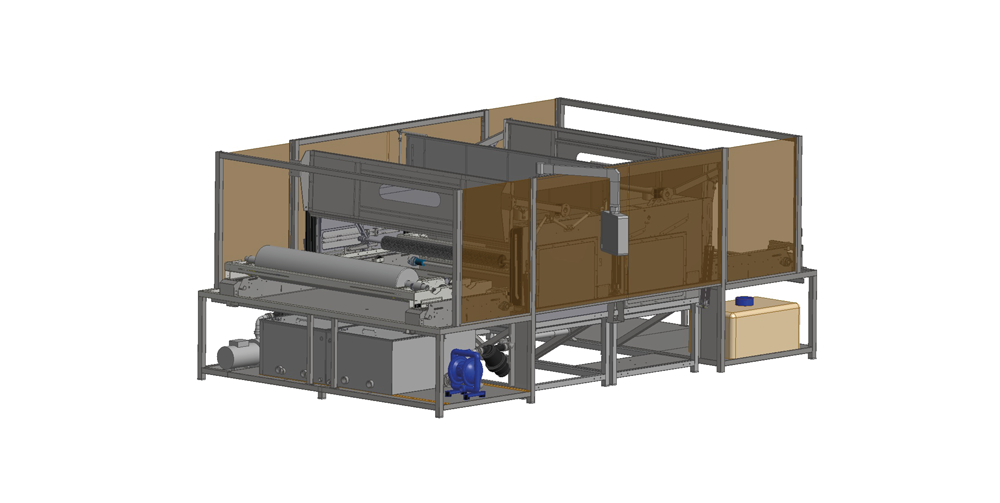

MCC 2-STAGE WR

1 washing station, 1 rinse and drying station.

8-12 CYLINDERS PER HOUR

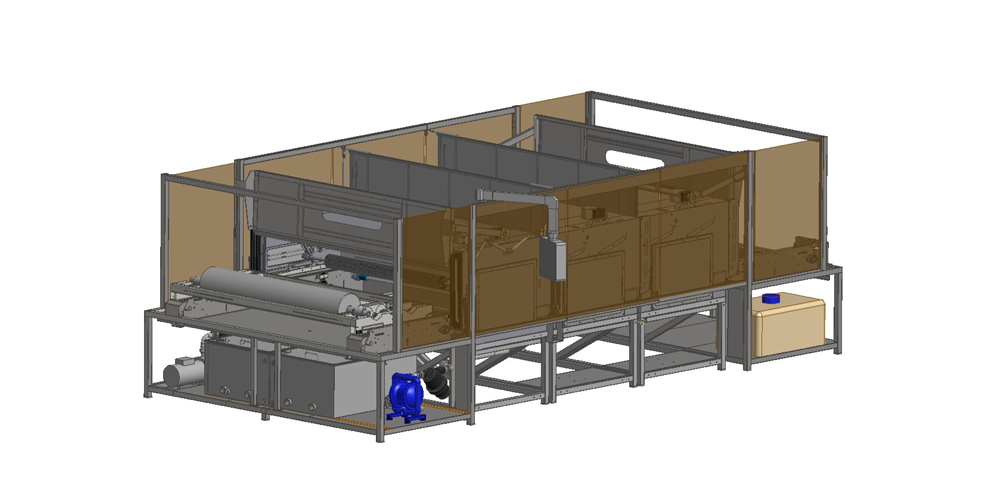

MCC 3-STAGE WWR

2 washing stations, 1 rinse and drying station.

6-22 CYLINDERS PER HOUR

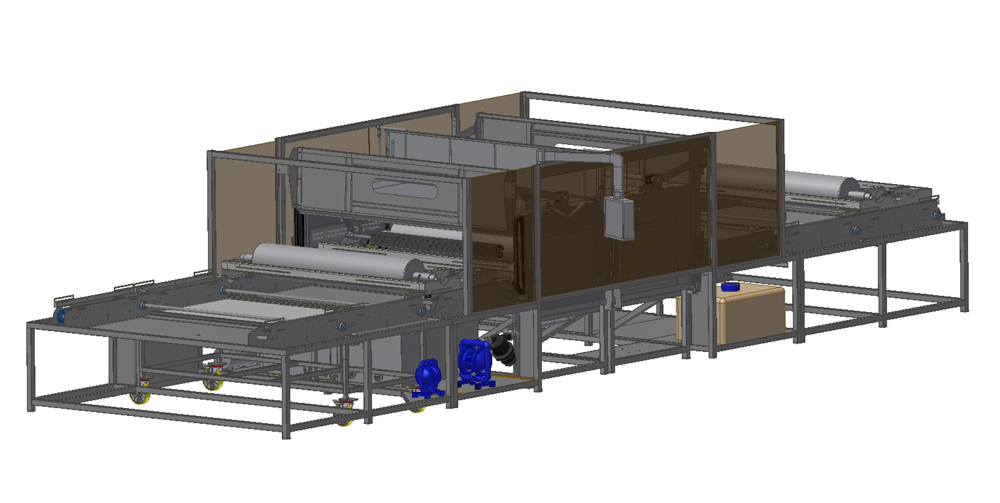

MCC 2-STAGE WR with extra buffer sections

1 washing station, 1 rinse and drying sections & 2 extra buffer sections (more buffer space for handling).

8-12 CYLINDERS PER HOUR

How does it work?

The Multi Cylinder Cleaner works with environmentally friendly cleaning liquid, which is specially made for cleaning of cylinders used with all types of ink.

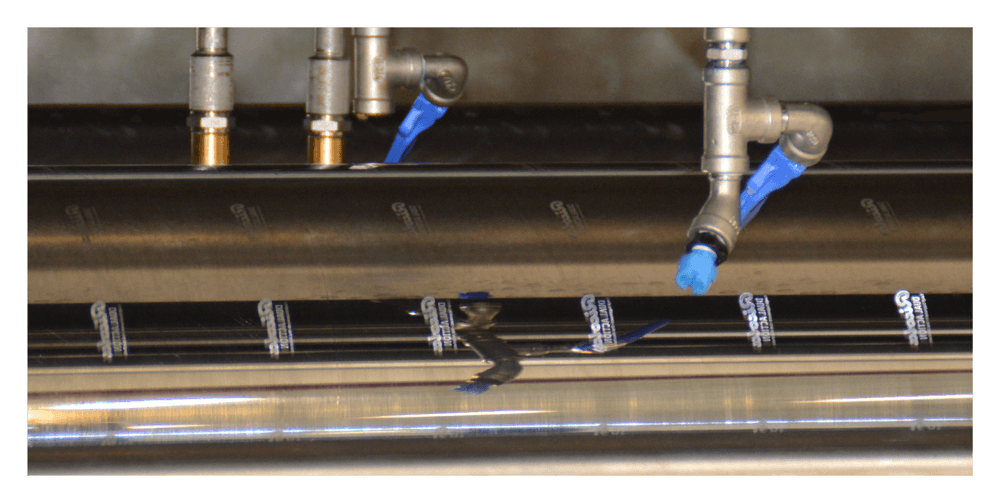

The water from the high-pressure rinse is automatically led directly to the drain, to a tank for re-use.

The cylinders are placed on the trolley at the printing machine and driven to the washing unit.

The trolley is then loaded to the loading station.

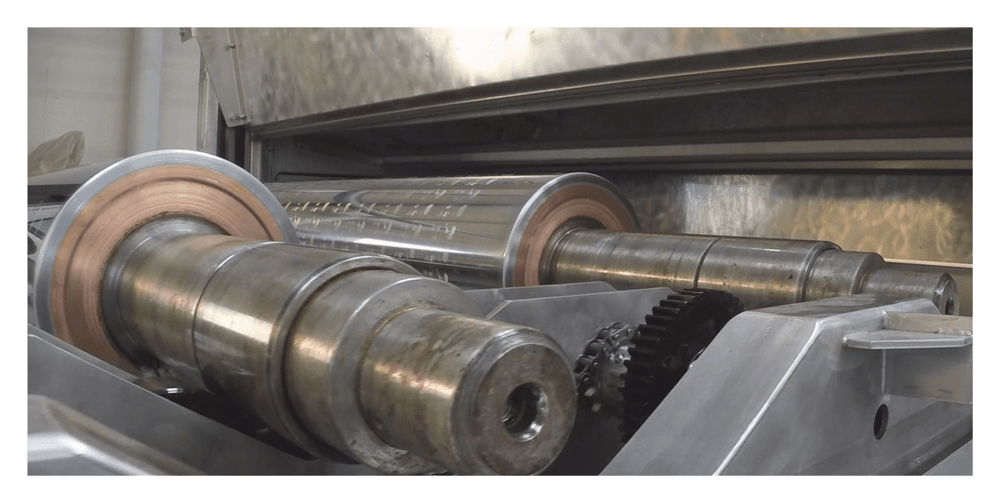

When the start button is pressed, the cylinders are automatically loaded into the machine by the automatic conveyer system and the doors close to separate the outside environment from the washing area.

While the washing of the first cylinders is taking place, additional cylinders can be loaded onto the machine’s loading station.

After a pre-set period, the first washing stage of the first cylinders is finished and they are automatically conveyed to the rinse stage of the cleaning process.

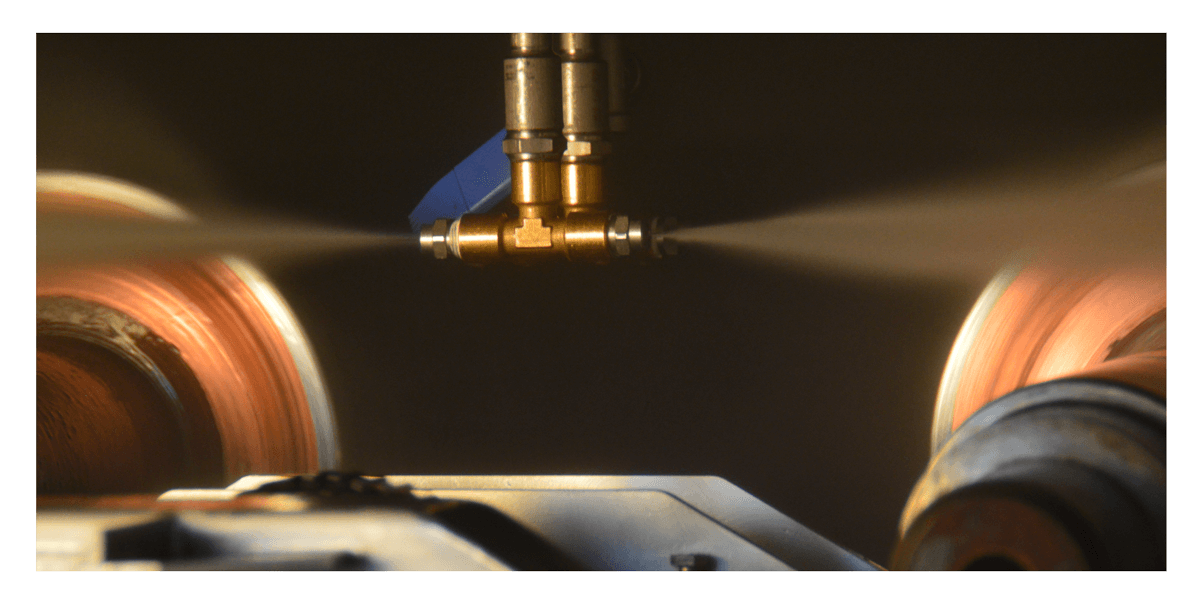

The cylinders are rinsed with water at a high-pressure. The high-pressure rinse nozzles move along the cylinders during the rinse.

Each cylinder trolley is moved through the washing stages and the process continues until the loading station is empty and all cylinders have been conveyed automatically to the unloading station on the machine.

When the cleaning cycle has ended the cylinders are automatically transported to the unloading station by the conveyer system.

Take your handling to the next level!

Combining the MCC with a logistic system creates a loop system making it possible to load a full job of 12 or more cylinders, thus ensuring a continous flow of cylinders through the cleaning process.