Cleaning plates properly and in a gentle and safe way is essential. With an unclean or broken plate, you will have quality issues with your print.

Both manual cleaning and automated cleaning are well-known in the industry, but which method is the best and most cost-efficient for your company? Cleaning plates properly and in a gentle and safe way is essential. Without a clean plate, you will not get proper print quality and with a broken plate due to poor cleaning, you will have quality issues with your print. Area sales manager, Mette Laursen, explains why focus on proper plate cleaning is essential:

“Plate cleaning equipment in general is not seen as something you make money on - only the presses do. But when it comes to plate cleaning it should be different, because one of the biggest pains for print houses is when the press is not running and that is very very costly.”

2 types of plate cleaning

There are benefits to both manual cleaning and automated cleaning and one method does not exclude the other. The choice is more dependent on what your specific needs are. Below we will describe each method further and highlight both pros and cons.

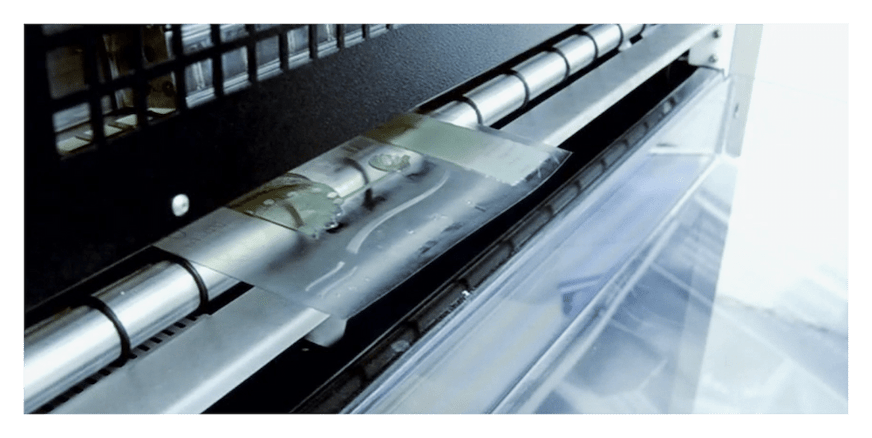

1. Automated plate cleaning

Automated plate cleaning is the process of using specialized machines or equipment to automatically clean printing plates without the need for manual intervention. This process typically involves using a cleaning solution and specialized brushes or rollers to remove ink and debris from the plate surface.

Automated plate cleaning systems can offer several benefits over manual cleaning, including increased efficiency, consistency, and reduced labour costs.

| PROS | CONS |

|

✔️ Effective and constant cleaning flow ✔️ Limited manpower needed ✔️ Effective cleaning of all ink types |

❌ Larger start-up investment ❌ System requires maintenance |

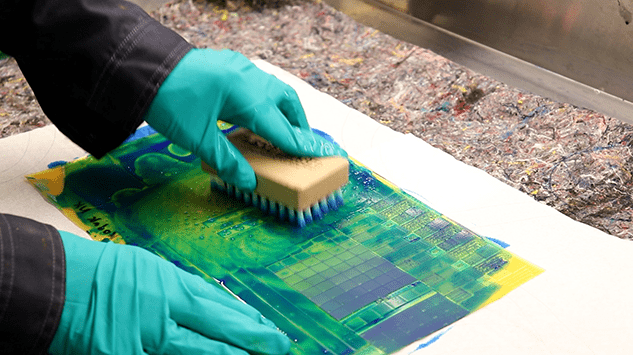

2. Manual plate cleaning

Manual printing plate cleaning refers to the process of manually cleaning printing plates using cleaning solutions and materials such as brushes or cloths.

Printing plates can become dirty or contaminated with ink or debris over time, which can affect print quality and consistency. Manual cleaning is a way to remove these contaminants and ensure that the printing plates are clean and ready to use.

The process typically involves applying a cleaning solution to the plate and using a brush or cloth to scrub away any ink or debris. The plate is then rinsed with water and dried before it is ready to be used again.

| PROS | CONS |

|

✔️ Low or no start-up investment ✔️ Requires less space ✔️ Well-known method |

❌ Inconsistent cleaning quality ❌ Time-consuming |

What can you gain from an automated plate washing solution?

If you want to know more about how an automated cleaning system can help your printing business, then download our guide “Manual or Automated plate cleaning” here.

You can also view the below video with Area Sales Manager Mette Laursen where she explains more about the importance of proper plate cleaning: