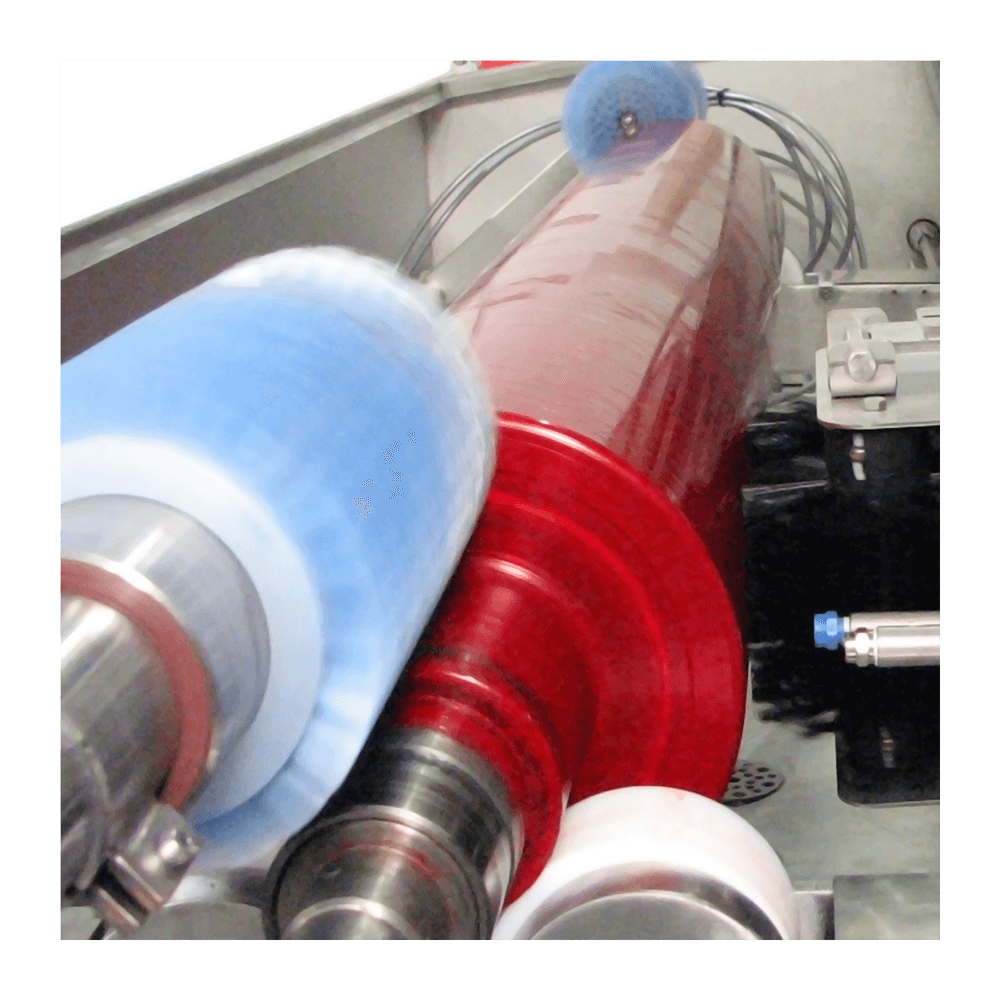

For 30 years Flexo Wash has provided leading cleaning solutions to the gravure industry. Our large equipment range reflects the flexibility needed in the industry. We provide two categories of units for cylinder roll cleaning, which are single/double cylinder cleaning machines and multiple cylinder cleaning machines.

How to do gravure roll cleaning?

There are three different methods for gravure cylinder cleaning - manual cleaning with solvents, automated cleaning with solvents, and automated cleaning with non-solvents.

Manual cleaning with solvents

While manual cleaning has been a traditional method in the printing industry, its limitations are hard to ignore, especially when dealing with gravure cylinder cleaning. The use of heavy cylinders and tools can lead to inconsistent cleaning results, particularly evident in gravure roll cleaning. The removal of built-up ink at the end face of the cylinder becomes even more challenging, making it necessary to add additional mechanical tools. This method not only poses health and safety risks to employees but also tends to become a bottleneck in production due to limited capacity.

Automated cleaning with solvents

Automated cleaning systems using solvents offer a more efficient alternative to manual cleaning, addressing the challenges associated with gravure cylinder cleaning. These systems ensure a constant and effective cleaning flow, capable of handling various ink types for high-quality results. However, the handling of solvents still introduces health and safety concerns, and the system requires a dedicated ATEX room. Despite the larger start-up investment, the long-term benefits include lower quality costs and increased production output.

Automated cleaning with non-solvents

Automated systems using non-solvents are an excellent choice, particularly for gravure roll cleaning. This environmentally friendly alternative offers the same high-quality cleaning without the need for an ATEX room. Placed conveniently next to the printing press, these systems not only enhance working conditions but also open up new possibilities for cylinder logistics, reducing the need for heavy manual handling.

What should you consider with gravure cylinder cleaning?

Before you make a choice about what methods is best for your production there are a few things you should consider. There are pros and cons to both manual and automated cleaning, and whether you prefer solvents or non-solvents is dependent on many things for example the ink type you use.

At Flexo Wash, we can guide you towards the best solution for you no matter what your preferences are. Start your journey towards better cylinder cleaning now.

Download our guide, where you can find a quick overview of the methods for cleaning cylinders, pros and cons, and a very helpful scoring board to figure out what method is best for your gravure cylinder cleaning.